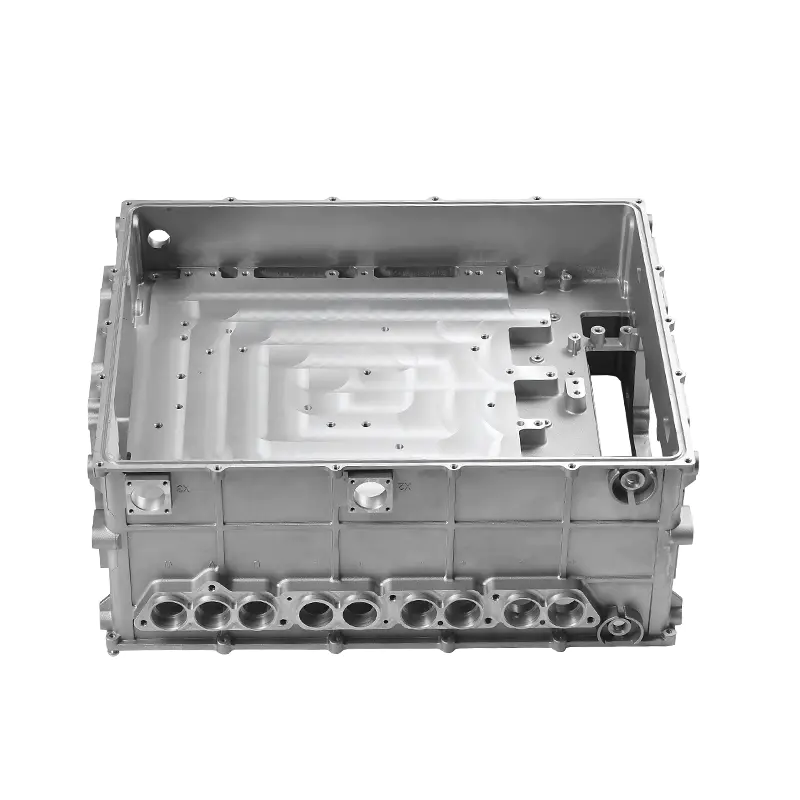

Le carter de boîte de vitesses joue un rôle clé de soutien et de protection dans l'ensemble du système de boîte de vitesses, et sa conception affecte directement la rigidité et la résistance aux chocs de la boîte de vitesses. Une structure raisonnable et une sélection de matériaux peuvent garantir que le boîtier reste stable lorsqu'il est soumis à un impact externe et à une charge interne, améliorant ainsi les performances globales et la durée de vie de la boîte de vitesses.

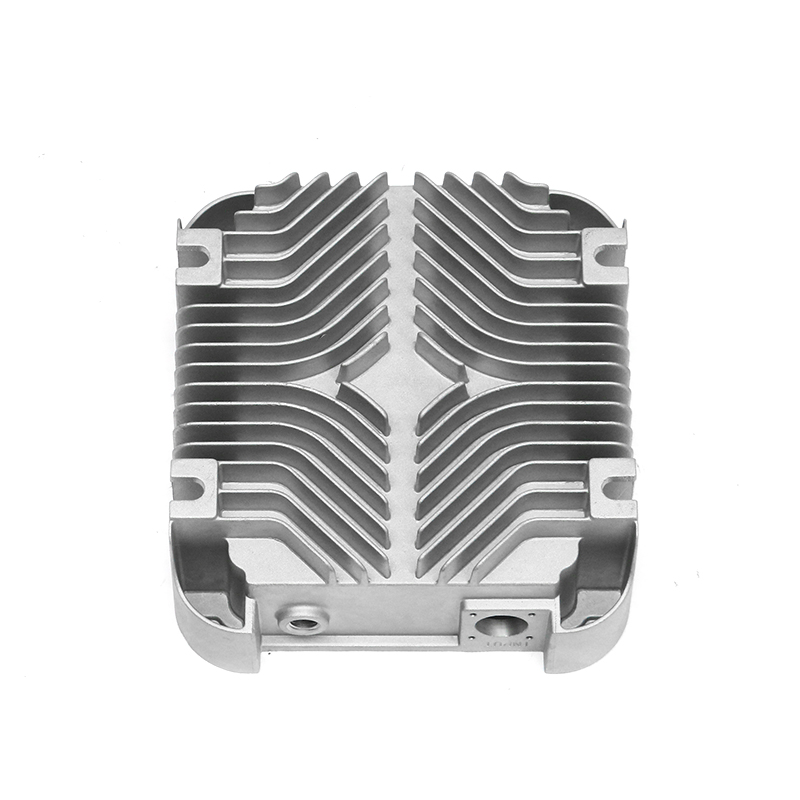

Un boîtier à haute rigidité peut réduire la déformation de la boîte de vitesses provoquée par les vibrations et les changements de charge pendant le fonctionnement, améliorant ainsi la stabilité de la transmission de puissance. Lorsque la boîte de vitesses fonctionne, l'engrènement interne des engrenages génère une force importante, qui nécessite un soutien suffisant de la part du carter, sinon cela pourrait entraîner un mauvais alignement ou une usure anormale des pièces internes de la boîte de vitesses. Par conséquent, la conception structurelle du boîtier doit répartir raisonnablement les points d'appui afin qu'il puisse résister uniformément aux forces provenant de différentes directions, éviter la concentration de contraintes locales et garantir que la boîte de vitesses peut rester stable dans diverses conditions de travail.

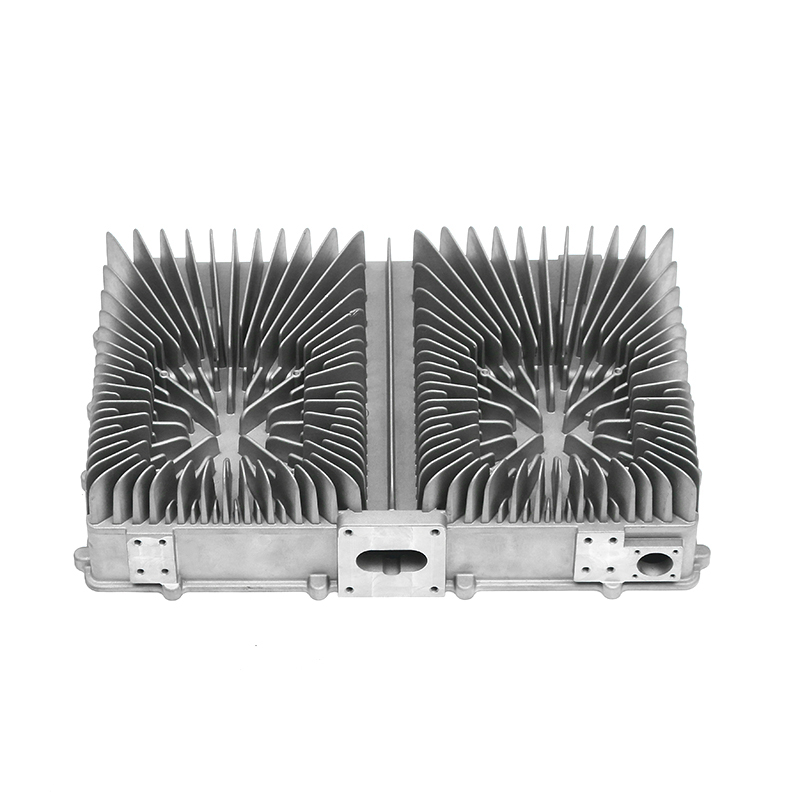

Le impact resistance of the housing is also crucial, especially in complex use environments, where the gearbox may be subjected to severe external impacts, such as bumps on the road, sudden changes in load or other external forces. If the housing is not impact-resistant enough, it may be deformed due to external impacts, and even affect the normal operation of internal parts. Therefore, in the design of the shell, materials with a certain toughness are usually used so that they can effectively absorb energy when impacted instead of directly transferring it to the internal structure. In addition, a reasonable structural layout, such as reinforcing ribs or multi-layer support structures, can further enhance the shell's impact resistance, so that it can still maintain normal operation in sudden situations.

Le choice of materials has an important impact on the rigidity and impact resistance of the shell. Usually, the shell is made of high-strength metal materials, so that it has good impact resistance while providing sufficient support. Different processing methods will also affect the final performance of the shell. For example, the casting process can improve the density of the material, thereby improving its strength and durability, while some special surface treatment technologies can enhance the shell's wear and corrosion resistance, so that it can maintain stable performance in different environments.

Le internal structure design of the shell also needs to take into account the needs of rigidity and impact resistance. Reasonable internal reinforcement structure can effectively disperse the load, so that the shell is not easy to deform when subjected to external force. At the same time, certain support points are usually designed inside the shell so that it can fit more closely with the internal parts, thereby reducing loosening caused by impact or vibration. In addition, some housings are thickened in certain areas to enhance local bearing capacity, thereby improving the stability of the overall structure.

Le design of the installation method and connection parts are also important factors affecting rigidity and impact resistance. A reasonable installation structure can ensure that the housing is tightly combined with other components to avoid affecting the normal operation of the gearbox due to looseness. At the same time, the fixing method of the housing needs to take into account the load changes in different environments to ensure that it will not be deformed or damaged due to stress accumulation during long-term use. In addition, some special connection methods, such as multi-point fixing or strengthening connectors, can also further enhance the stability and impact resistance of the housing.

Produits recommandés

Les produits fournis par des entreprises célèbres jouissent d'une grande confiance auprès des utilisateurs.